Rockinger RO-500 operation and review

- Rockinger RO500 Coupling Features

- Rockinger RO500 Sensor Operation

- How to operate a Rockinger RO500

- Installation and Operating Instructions for RO 50 Towing Hitch Systems

- Installation and Operating Instructions for RO 500 Towing Couplings

Robust construction, ease of use, and outstanding durability are why DeBruyn’s Transport, Maintenance Manager, Damien Allison specifies Rockinger RO-500 couplings for their west coast truck and dog fleet.

DeBruyn’s Transport, Maintenance Manager, Damien Allison specifies Rockinger RO-500 couplings for their west coast truck and dog fleet

Tourist brochure headlines paint an inviting picture of Tasmania’s west coast. “Visit alpine plains and temperate rainforests, see glacial valleys, picturesque rivers and windswept shorelines”. In peak tourist season, holidaymakers flock down the west coast for a day or two in their thousands.

But for transport operators like DeBruyn’s Transport, they know firsthand Tasmania’s west coast is a region that commands respect. It’s not an environment for the faint-hearted nor inadequate equipment. After all, for well over five decades, west coast communities and mines still rely on DeBruyn’s Transport for vital supplies.

Wind the clock back to shortly before sunrise on April 1, 1965, a solitary DeBruyn’s truck headed southwest on the newly completed Murchison Highway to the Mount Lyell Mining and Railway Company in Queenstown. This journey marked the start of the service that continues to this day.

Damien Allison added that a year later, DeBruyn’s Transport extended services to the Renison Tin Mine near Zeehan. “And, we still provide transport services to both these mining companies.”

Damien Allison added that a year later, DeBruyn’s Transport extended services to the Renison Tin Mine near Zeehan. “And, we still provide transport services to both these mining companies.”

DeBruyn’s reputation for its long-standing reliability on the west coast did not go unnoticed. Their willingness to diversify into other transport segments and do it well expedited the growth of this family operation. This diversification led to the establishment of depots in Launceston, Hobart and Devonport. At the time of writing, DeBruyn’s Transport currently employs over 200 people and run a fleet of 120 trucks, with more than 200 trailers and other specialised transport equipment.

Today, we were hitching a ride with Peter Cruse in the Mack Granite with Hercules quad dog; he drives on the run to the Kara magnetite mine to see firsthand how the Rockinger RO-500 coupling stands up to the rugged west coast operation.

Both Damien and Driver Peter Cruse agree that the one-handed operation of the Rockinger RO-500 coupling is a simple, safe procedure.

Both Damien and Driver Peter Cruse agree that the one-handed operation of the Rockinger RO-500 coupling is a simple, safe procedure.

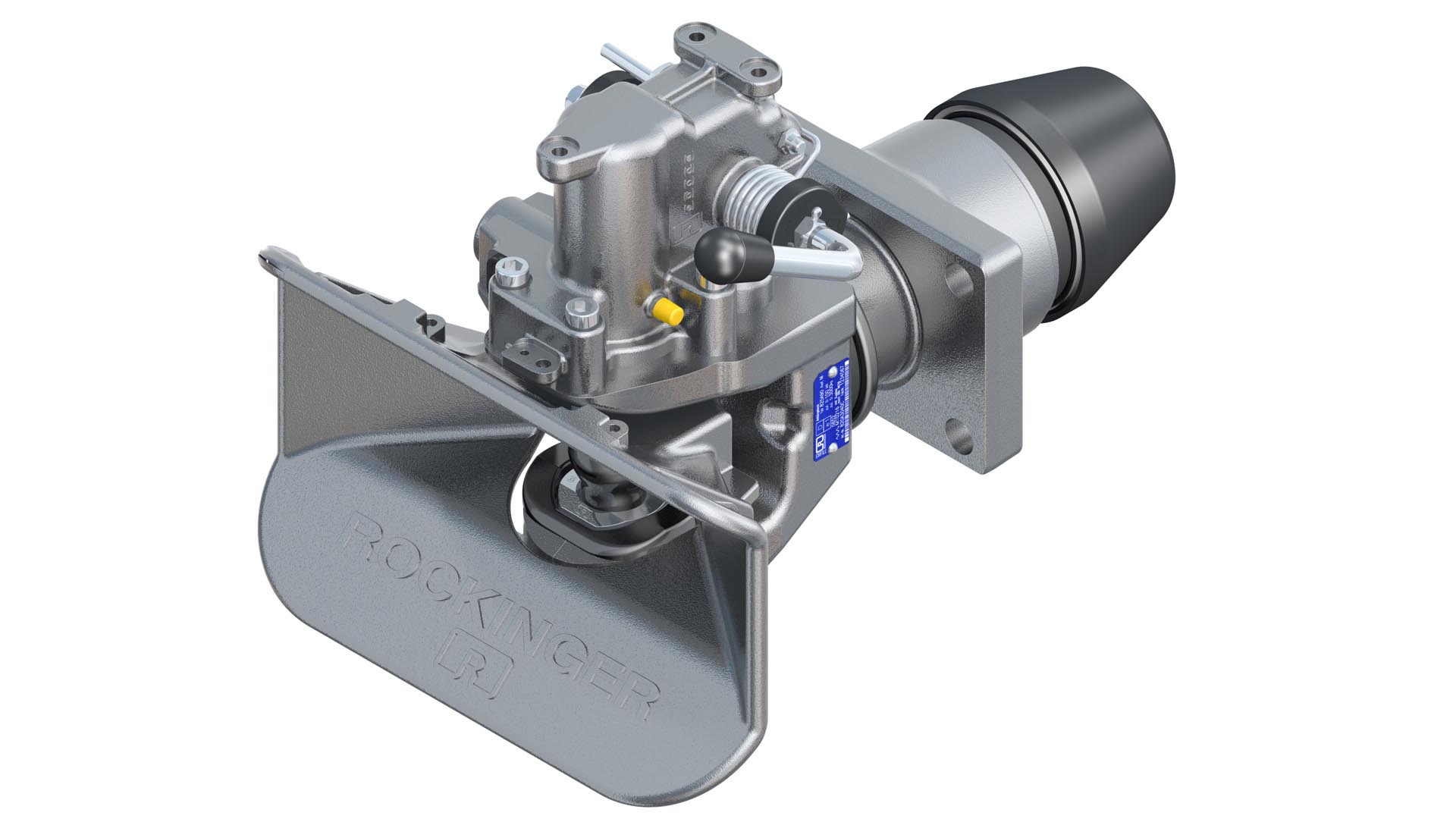

“To uncouple the trailer, it’s just a matter of raising the protective flap, disconnect the airlines and lift one lever,” Peter said. “And when it comes to coupling up the trailer, as soon as the eye of the drawbar makes contact with the trip lever in the coupling, the tow bolt drops into position, and the handle lowers. There is a bright red secondary safety indicator on the side that disappears when the coupling is locked. It’s that simple,” Peter adds.

“One of the biggest advantages for us with the Rockinger RO-500 compared to other competitor couplings is its ability to enable the drawbar to articulate a full 90-degrees,” Damien explained. “When the ships are running late, and we are trying to squeeze extra tonnes into the concentrate holding shed, there is very little room to jack-knife the dog trailer around. But the ability of these Rockinger RO-500 couplings to go a little past the 90-degree point is a huge advantage for us. It mightn’t sound like much, but it means the difference between saving 15-20 minutes unhooking a trailer each load. That time soon adds up.”

Jost Australia’s National Training Manager, Bob Martin, was on hand to explain some of the more outstanding features of the Rockinger RO-500 coupling.

Jost Australia’s National Training Manager, Bob Martin, was on hand to explain some of the more outstanding features of the Rockinger RO-500 coupling.

“One of the advantages with the Rockinger RO-500 for DeBruyn’s Transport magnetite operation is that the top housing is securely bolted down to the main body to prevent dirt and dust ingress into the upper workings of the coupling,” Bob explained. Another advantage of the model is its ability to be opened with the mouth in any position. So it doesn’t have to be dead straight to uncouple,” Bob added.

“However, once the lever has returned to the neutral position, that is when it’s ready for coupling, there is a small lock that will hold the mouth of the unit in the straight-ahead position for ease of coupling when required,” Bob continued.

“However, once the lever has returned to the neutral position, that is when it’s ready for coupling, there is a small lock that will hold the mouth of the unit in the straight-ahead position for ease of coupling when required,” Bob continued.

According to Damien, the key to the simplicity of the Rockinger RO-500 is in its design. When you first glance at the coupling unit, it appears so simple, yet it’s obvious there’s a significant amount of engineering that went into making the coupling function seamlessly.

“There are very few moving parts in the Rockinger RO-500,” Bob explained. “It’s very straightforward to do a changeover or carry out general servicing and maintenance on these couplings. We hear all the time from operators who work in dusty, dirty environments like DeBruyn’s Transport that Rockinger’s dust ingress protection is certainly a welcomed feature because it doesn’t allow for any debris to get inside the mechanism,” Bob said. “Outback road train operators certainly benefit from this feature.”

“At Jost, safety is paramount,” Bob explained. “It is a big part of what guides us during the development of new products and leads us to design more efficient and safer products. Jost has research and development teams scattered worldwide that work toward this goal. As a result, all our products, including the Rocking RO-500, are constantly evolving. But best of all, customers can retrofit any of the new product enhancements or additional options at a later date to the RO-500 if their application changes.” Bob added.

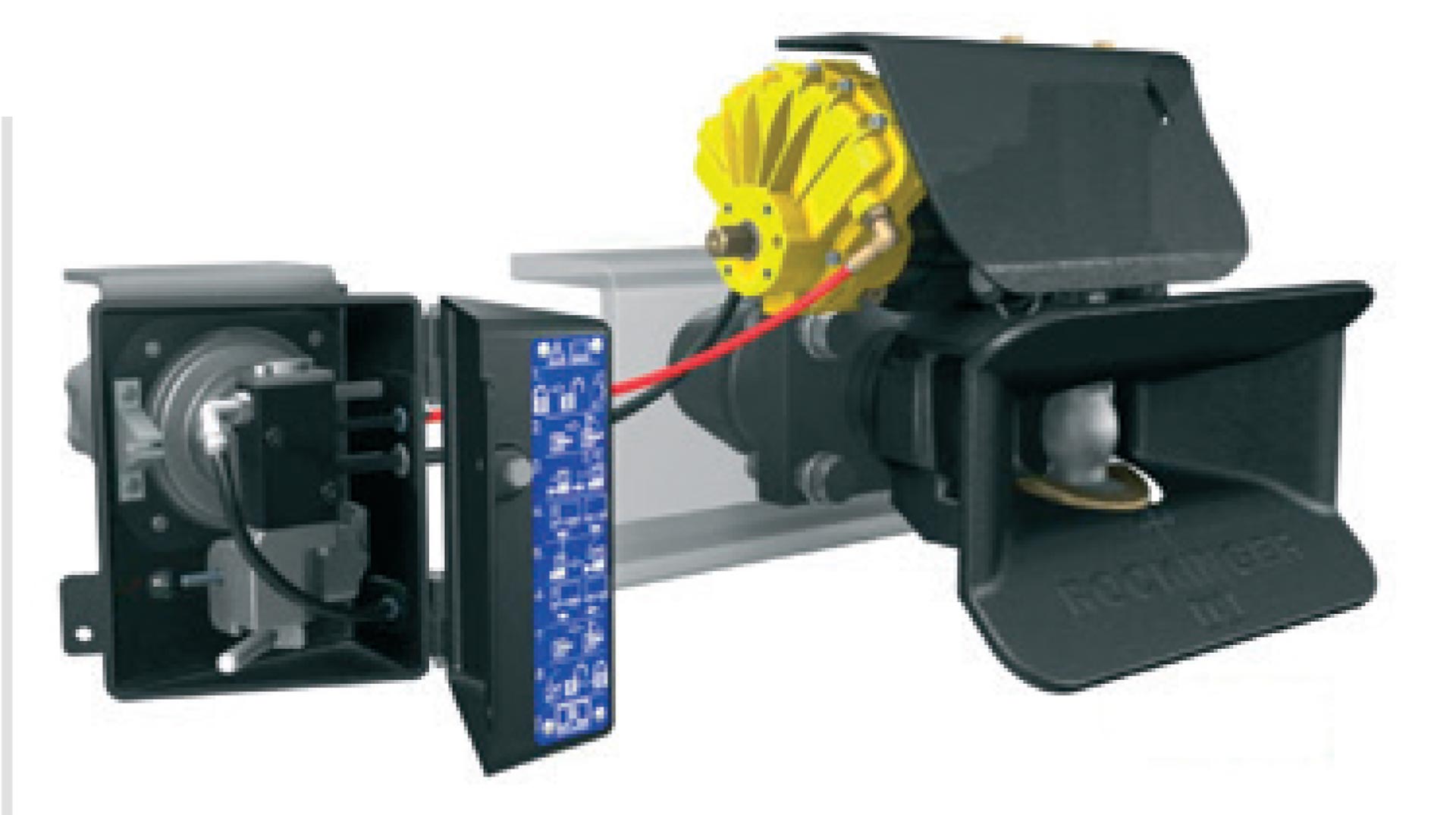

One recent product enhancement is the optional pneumatic coupling release upgrade. This new option enables the Rockinger RO-500 coupling to be remotely released pneumatically. There is no need for the driver to manually release the coupling at the truck’s rear with this option fitted.

“In certain industries like roads and construction, where truck and trailers carry bitumen products, at temperatures up to 300°C, our commitment to technology greatly improves operator safety,” Bob explains. “This is a significant safety factor in coupling design because it now means the drivers do not need to go behind the vehicle, which reduces the hazard of working around hot materials.”

“In certain industries like roads and construction, where truck and trailers carry bitumen products, at temperatures up to 300°C, our commitment to technology greatly improves operator safety,” Bob explains. “This is a significant safety factor in coupling design because it now means the drivers do not need to go behind the vehicle, which reduces the hazard of working around hot materials.”

Other new safety enhancements Jost recently rolled out include an upgrade to the sensor that monitors the locking function of the coupling and jack-knife warning sensor. These sensors alert the driver via a dash-mounted indicator when the coupling is correctly connected, uncoupled, or potential drawbar damage is imminent.

“In addition to PBS operations like DeBruyn’s Transport, the Rockinger RO-500 is rated for road train applications up to 285kN.

“In addition to PBS operations like DeBruyn’s Transport, the Rockinger RO-500 is rated for road train applications up to 285kN.

“Our Rockinger RO-500 couplings, like our Jost fifth-wheels, are so easy to use,” Damien concluded. “They’re simple to operate, and it doesn’t take a rocket scientist to understand how they work. We’ve been impressed with their longevity, but the ability to maintain them quickly and easily certainly makes them a winner in my book.”