Understanding the importance of S-Cam brake balance in heavy-duty trucks is a fundamental part of truck safety and will go a long way to prevent brake failure.

Many operators often see brake components as a costly profit eating commodity, consequently and, sadly, they opt for the lowest priced option when selecting replacement parts. However, regulators have grave concerns that these cheaper inferior quality components now available on the Australian market don’t live up to operator expectation for operational functionality, serviceability and reliability. Even more concerning to heavy vehicle safety is mismatched brake components that ominously compromise the braking balance of a vehicle combination.

Kerry Hingston’s Restored Scania 1973 LB80

Heavy vehicle brake imbalance creates dangerous vehicle stability issues. While incorrectly adjusted brakes are one major cause of S-Cam brake imbalance. Incorrect replacement brake components are another significant cause, especially if the parts vary from the left-hand side to the right-hand side on the same axle. Any deviation in brake parts from the left or right side of the axle’s brake groups, even down to the brand or age of components, negatively impacts brake balance.

The fewer axles in the group, the more imperative the brake balance becomes. The most susceptible configuration to poor brake balance induced stability issues is a short wheelbase 4×2 prime mover.

“Long-Stroke” 76.2mm (3-inch) brake chambers are now the more preferred original equipment fitment by heavy vehicle OEMs. However, it is essential that drivers and service personnel recognise the type of brake components fitted to the vehicle. And, it is imperative that if component replacement is necessary, “like for like” parts are installed.

“Long-Stroke” 76.2mm (3-inch) brake chambers are now the more preferred original equipment fitment by heavy vehicle OEMs. However, it is essential that drivers and service personnel recognise the type of brake components fitted to the vehicle. And, it is imperative that if component replacement is necessary, “like for like” parts are installed.

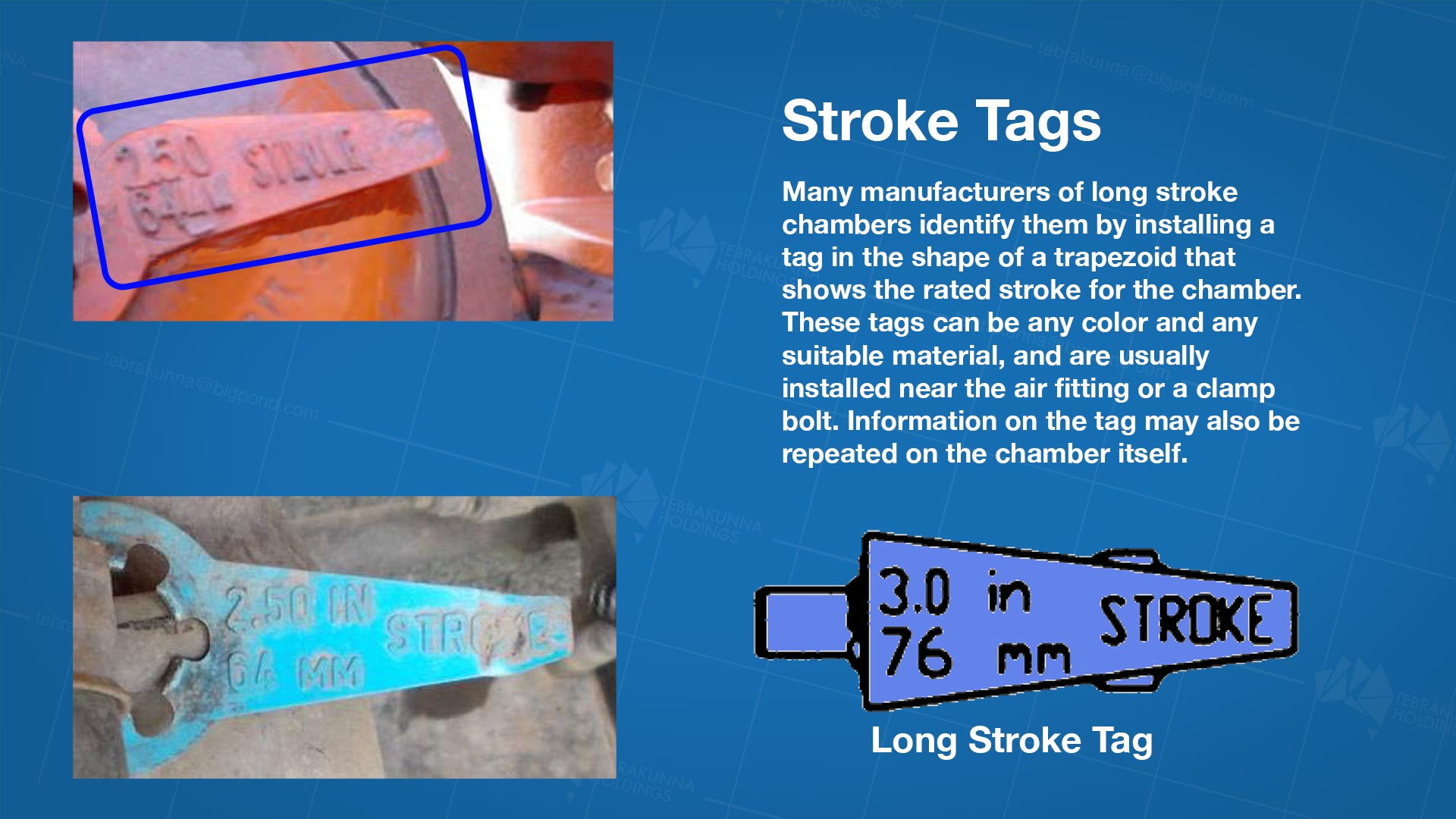

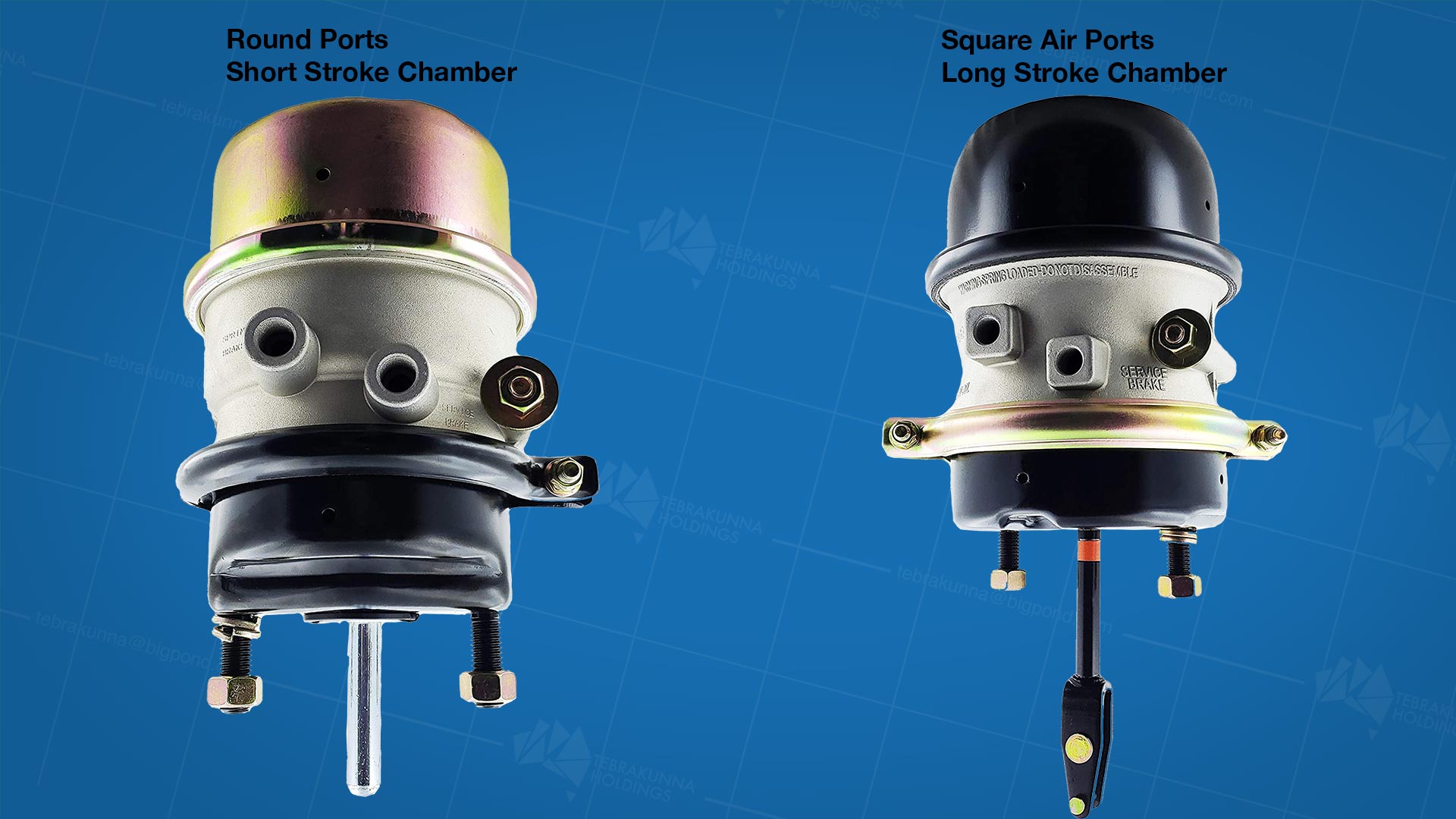

To easily differentiate between the “Standard-Stroke” 63.5mm (2.5- inches) and the “Long-Stroke” brake chambers, the brake manufacturers established the following forms of identification for spring brakes chambers:

- square air-inlet ports;

- diaphragm replacement instructions embossed into flange case;

- a triangular-shaped I. D. tag secured to the service-side clamp band bolt:

On service chambers, the identifiers are:

- 12mm high square embossment on top of pressure cap;

- diaphragm replacement instructions embossed into pressure cap;

- a triangular moulded I.D. tag secured to clamp-band bolt

Although Standard-Stroke and Long-Stroke brake chambers deliver effectively the same force output at 44.5mm (1.75-inches) of stroke, the functional properties and performance beyond that point are dramatically different. Long-Stroke brake chambers provide significantly greater braking force beyond the point where the Standard-Stroke chambers cease to function. For this reason, Standard-Stroke and Long-Stroke chambers should never be installed on the same axle.

Although Standard-Stroke and Long-Stroke brake chambers deliver effectively the same force output at 44.5mm (1.75-inches) of stroke, the functional properties and performance beyond that point are dramatically different. Long-Stroke brake chambers provide significantly greater braking force beyond the point where the Standard-Stroke chambers cease to function. For this reason, Standard-Stroke and Long-Stroke chambers should never be installed on the same axle.

S-Cam Operation

During hard or continuous braking, the heat generated during braking causes the drum to “grow” or expand. Consequently, the ability of a Standard-Stroke chamber to deliver adequate pressure of the lining against the ever-expanding drum is subsequently limited by its stroke and performance characteristics. Therefore, as Standard-Stroke chambers exceed 50.8mm (2-inches) of travel, a driver will begin to feel a “brake fade” experience. This situation is due to the reduced force output of the chamber as it moves closer to its maximum travel position of 63.5mm (2.5-inches). When the brake chamber stroke is at or near that point, that brake will cease to provide any braking force.

As a result, if a Standard-Stroke 63.5mm (2.5- inches) and a Long-Stroke 76.2mm (3-inch) brake chamber is installed on the same axle, an imbalance may exist, adversely affecting the stopping capability of the vehicle. This condition is especially true when the Standard-Stroke chamber exceeds its recommended 50.8mm (2-inches) readjustment limit. Consequently, this mismatch of brake components possibly will result in the vehicle jerking toward the side where the Long-Stroke chamber is located. The brakes fitted with the Long-Stroke chamber by now are doing the majority of the braking.

During everyday brake applications, this situation may go unnoticed by the driver. However, it could cause vehicle instability during emergency braking situations. Therefore, it is critical that technicians identify which type of brake chamber is fitted to the truck or trailer and crucial that the chambers be replaced “like for like”.

The advantages derived from having a heavy-duty truck and trailer combination equipped with Long-Stroke 76.2mm (3-inch) chambers are well documented and include; improved braking efficiency, increased reserve stroke and reduced out-of-adjustment infringement notices. However, unless the brake system is properly maintained and serviced, realising the benefits listed above will be unachievable.

Free Stroke

Free Stroke

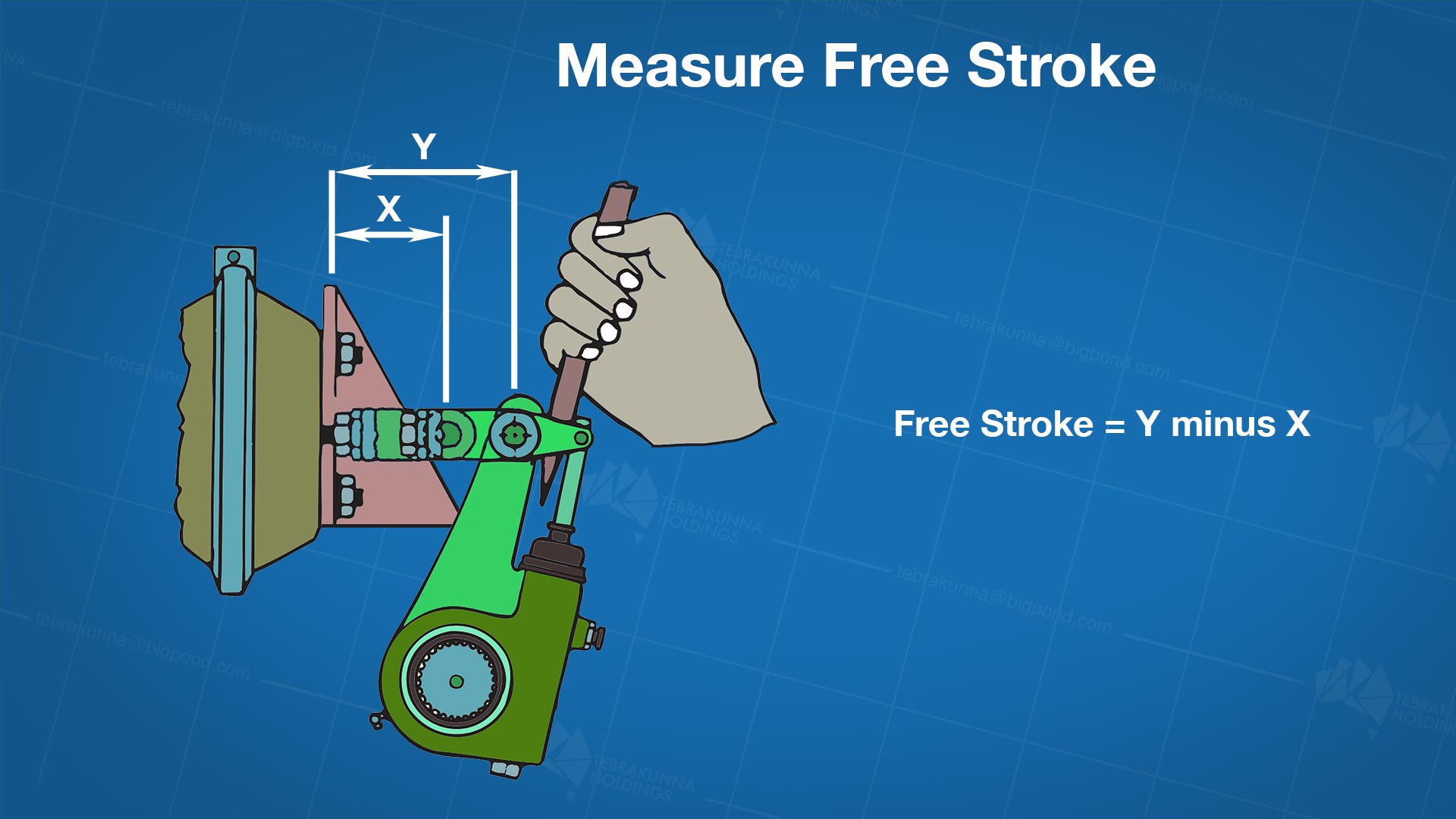

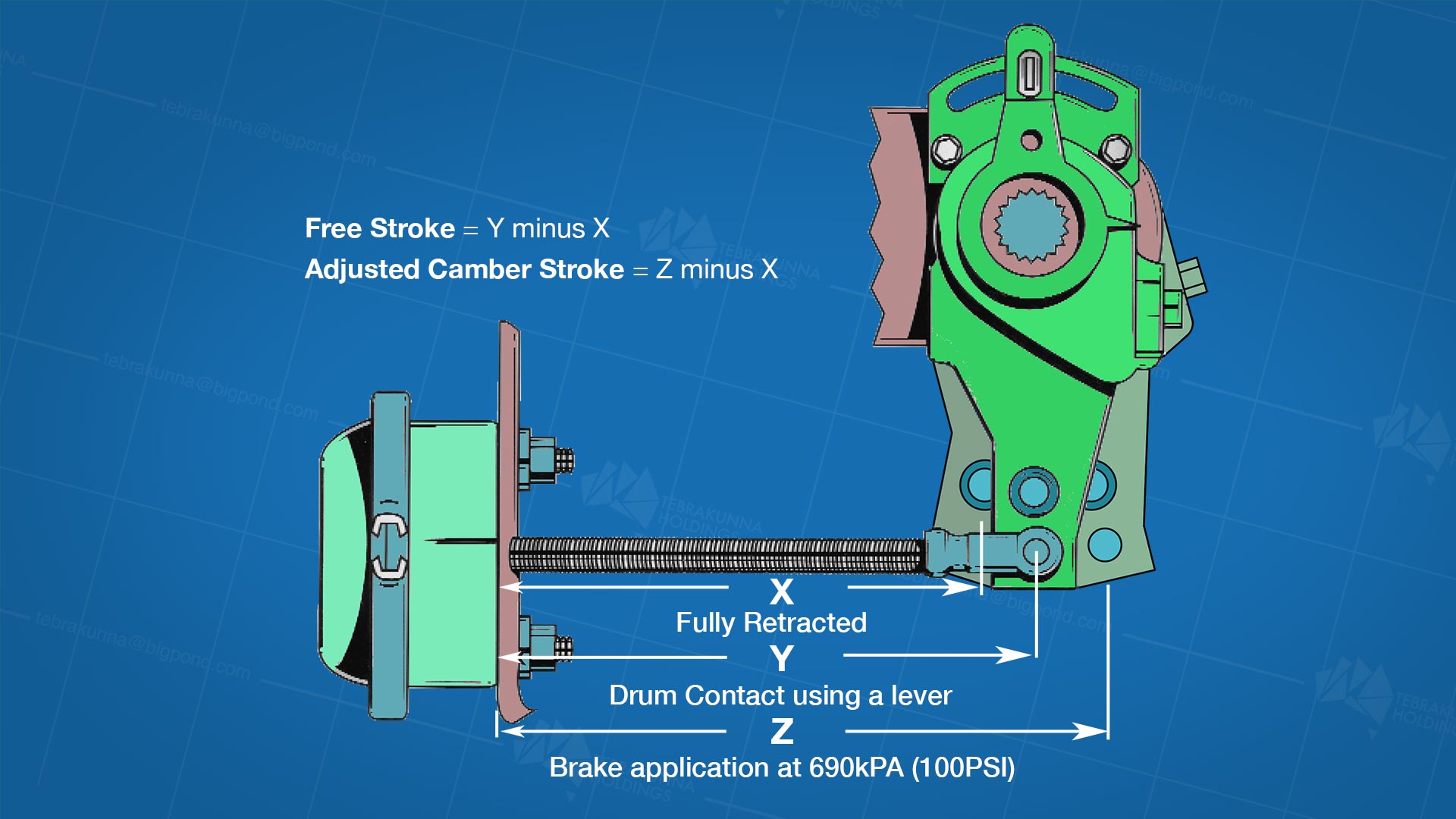

Free stroke describes the amount of movement of the adjuster arm required to move the brake shoes up to the drum or the clearance between the drum and brake lining. During the vehicle service or while performing preventive maintenance, the free stroke and adjusted chamber stroke must be checked and restored to the manufacturers recommended specifications.

As a general rule, the in-service free stroke for an S-Cam brake is between 12.7-19 mm (0.5-0.750-inch) but always refer to the manufacturer’s manual for the correct measurement. However, the free stroke measurement above is generally acceptable if the adjusted chamber stroke is within limits shown in Table-A.

To check the Free Stroke.

Release the brakes. Measure from the chamber face to the centre of the clevis pin. Take a large size screwdriver or pry bar and use it as a lever to move the brake slack adjuster until the brake shoe contacts the drum. Now measure the distance again from the face of the chamber to the centre of the clevis pin. The difference is the free stroke.

A word of caution here! Never set the free stroke shorter than 12.7mm (0.5-inch) because if the measurement is too short, linings can drag. Consequently, prematurely wearing out brake components, truck performance will deteriorate, and fuel usage will increase.

To check the Adjusted Chamber Stroke.

To check the Adjusted Chamber Stroke.

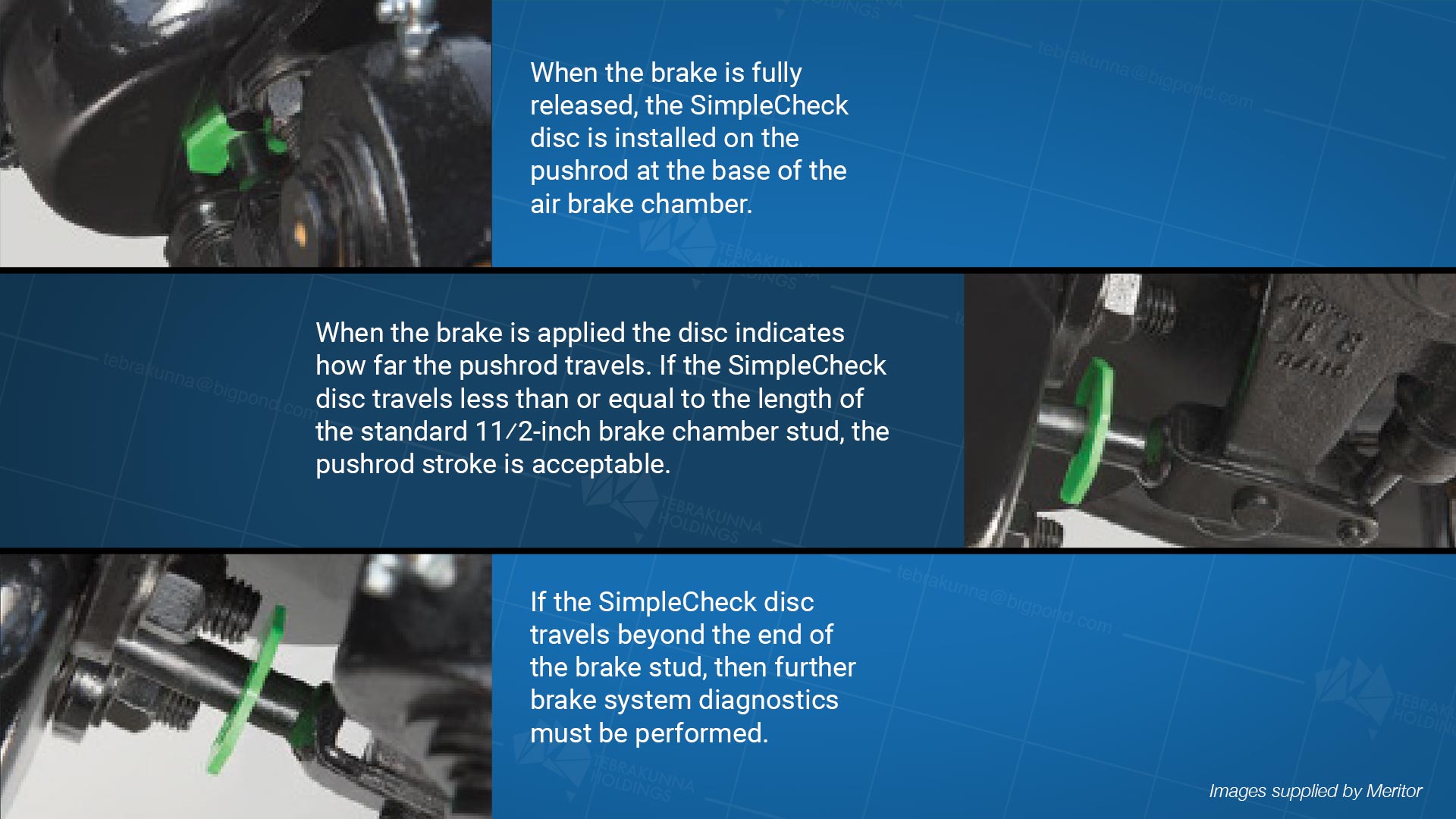

Use the following procedure to check the pushrod travel or adjusted chamber stroke. The easiest way to perform this check is by using Meritor’s SimpleCheck stroke indicator tool (Part#M820625). They’re only a couple of dollars each.

First, chock the wheels to prevent the truck from moving because you will need the brakes released during this procedure. To use Meritor’s SimpleCheck stroke indicator tool:

- Ensure that the vehicle has full air pressure, which is approximately 690kPA (100 psi).

- Release the parking brake; when the brake is fully released, place the SimpleCheck disc over the brake pushrod and firmly press it up to the base of the brake chamber.

- Apply the brakes.

The SimpleCheck disc moves along the pushrod during the brake application and indicates the distance of pushrod travel.

If the SimpleCheck disc travels less than or equal to the length of the standard 38mm (1.5-inch) brake chamber stud, the pushrod stroke is within the acceptable tolerance. However, if the SimpleCheck disc travels beyond the brake stud’s end, you must perform further brake system diagnostics.

If the SimpleCheck disc travels less than or equal to the length of the standard 38mm (1.5-inch) brake chamber stud, the pushrod stroke is within the acceptable tolerance. However, if the SimpleCheck disc travels beyond the brake stud’s end, you must perform further brake system diagnostics.

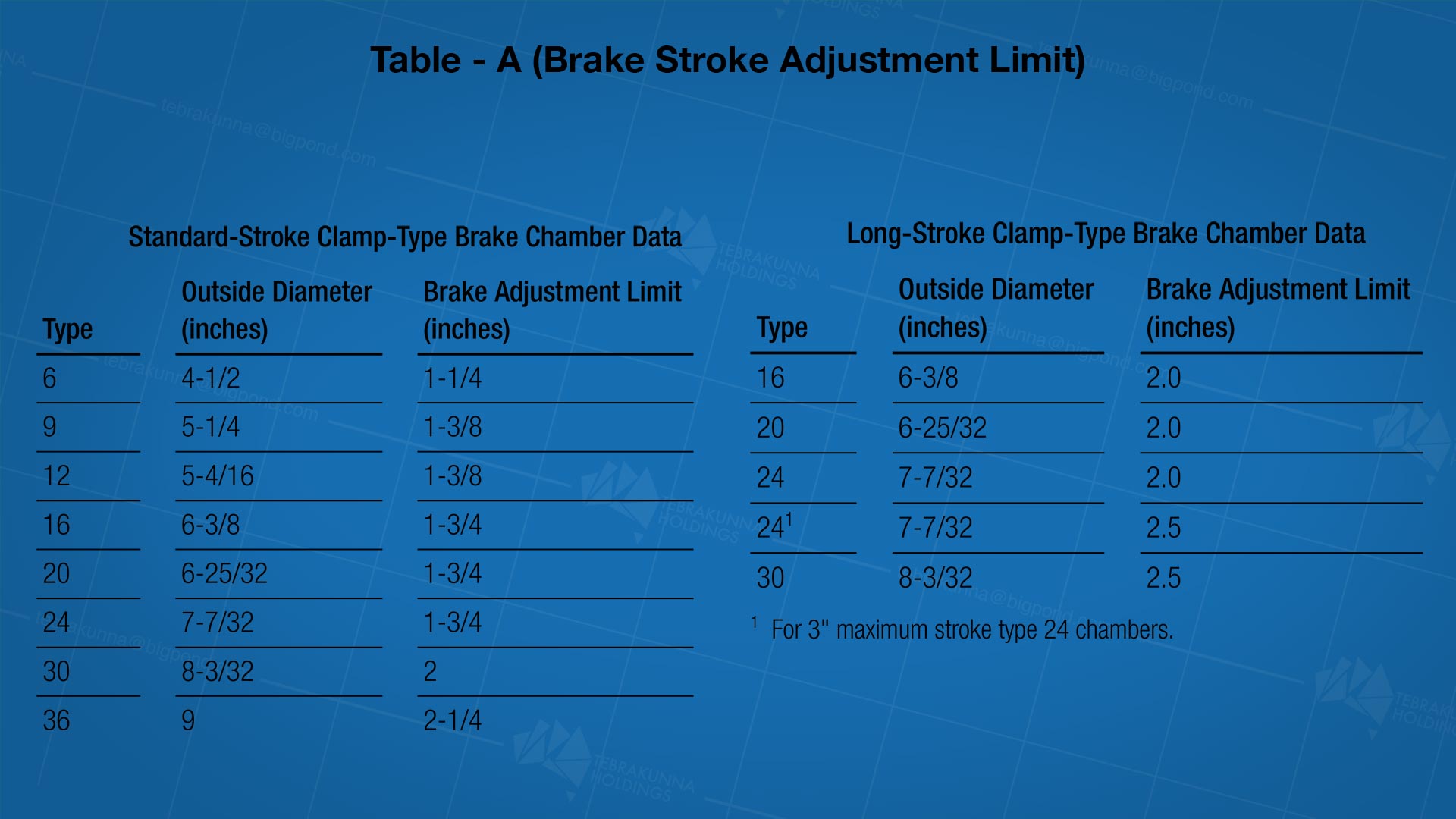

On the other hand, if you don’t have access to Meritor’s SimpleCheck stroke indicator tool, you can still perform this check the “old-school” way. Again, release the parking brake and when the brake is fully released, mark the pushrod with a paint pen where the pushrod exits the brake chamber. Get an assistant to apply the brakes. Now measure the distance from the mark on the pushrod to where the pushrod enters the brake chamber. This distance is the adjusted chamber stroke. You can confirm the stroke length is correct for the size and type of brake chamber fitted to the vehicle by referring to Table-A.

On the other hand, if you don’t have access to Meritor’s SimpleCheck stroke indicator tool, you can still perform this check the “old-school” way. Again, release the parking brake and when the brake is fully released, mark the pushrod with a paint pen where the pushrod exits the brake chamber. Get an assistant to apply the brakes. Now measure the distance from the mark on the pushrod to where the pushrod enters the brake chamber. This distance is the adjusted chamber stroke. You can confirm the stroke length is correct for the size and type of brake chamber fitted to the vehicle by referring to Table-A.

Table-A

The ability to safely stop a heavy vehicle combination is arguably the most critical safety factor of a truck’s operation. Compromising a vehicle’s braking system with mismatched or inferior parts is only asking for trouble.

The investment in quality brake components and having the brake system regularly inspected at a reputable workshop is cheap insurance and peace of mind for continued truck safety.