Elphinstone Engineering is redefining log haulage with the introduction of their ‘Self-Loader’ powerpack option to their EasyLoader trailer models. The new powerpack enables standard prime-movers to haul and operate logging trailers without the expense of specialised PTO and auxiliary equipment fit-up. Additionally, it is backwards compatible, meaning retrofitting the unit to older EasyLoader trailers is easily done.

The innovative concept of engineering the trailer combination to load themselves was primarily driven by the shortage and availability of new trucks.

The innovative concept of engineering the trailer combination to load themselves was primarily driven by the shortage and availability of new trucks.

“Our customers are finding it increasingly difficult to get purpose-built prime movers suitable for dedicated log trailers in time for the commencement of cartage contracts,” Graeme Elphinstone, Founder and Director of Product Design, said.

“Initially, we’ve designed the ‘Self-Loader’ powerpack option to suit our EasyLoader trailer combinations. The EasyLoader is a lightweight, versatile trailer platform which allows operators the flexibility to interchange trailers depending on their logging application at the time,” Graeme explained. “Their modular design includes bolt-on options and easy bolster adjustment to suit multiple log length requirements. As a result, it’s not uncommon for our customers to get more the many millions of kilometres out of our trailer sets if they are properly maintained. They are available from 19-meter Mini B-Double to 36.5-meter multi-bay B-Triples and A-Doubles.”

Download EasyLoader Brochure

Self-Loader Powerpack

Self-Loader Powerpack

“On the other side of the coin, some of our customers have diverse operations, including transporting other freight forms. Our new ‘Self-Loader’ powerpack option gives them better vehicle utilisation across their fleet with their prime movers. When not carting logs, they can easily uncouple their standard prime mover from our EasyLoader trailer set and operate the prime mover to another part of their operation without any tare weight penalty. Traditionally, dedicated log trucks have an additional hydraulic oil tank, PTO and robust cab guards, which while a necessity in logging applications are superfluous accessories in general freight that only add unnecessary tare weight to a prime mover.”

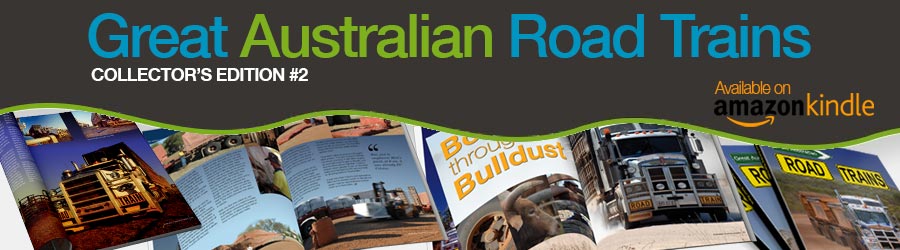

With the ‘Self-Loader’ powerpack option, all the hydraulics are located on the lead trailer. An electric start petrol engine drives the hydraulic powerpack. The Self-Loader powerpack option only adds approximately 200kg to the tare weight of the standard tri-tri EasyLoader B-Double trailer set.

The controls for the powerpack are conveniently located next to the engine. Additionally, a remote-control module is an option well worth considering as it enables the operator to move around the trailers when loading or unloading the unit.

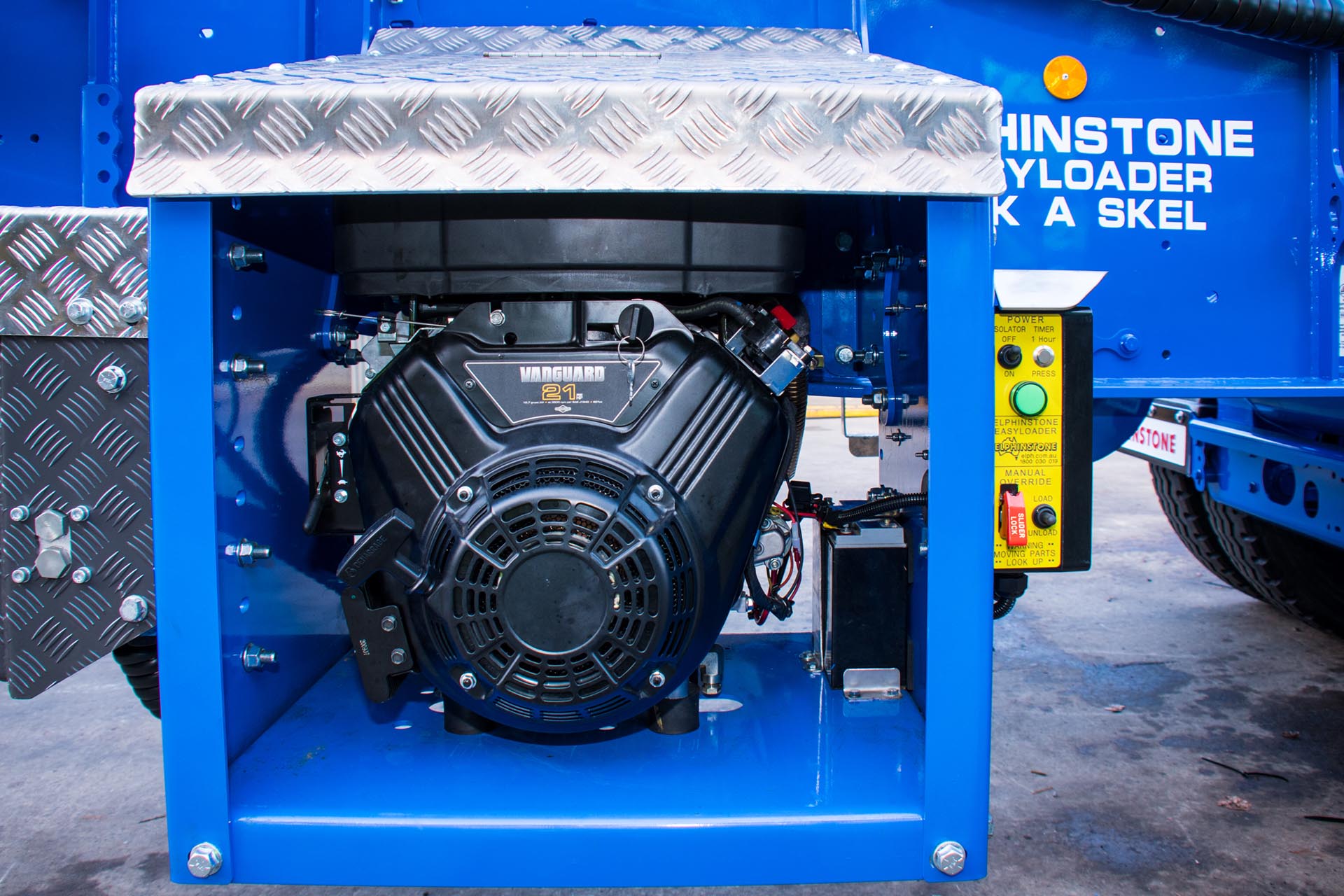

“We’ve retained the traditional under-bolster electrical and air coupling location, which suits most purpose-built log trucks,” Graeme informed. “However, we’ve added a front-mounted connection point to suit a standard prime mover with Suzi-Coil hoses with both standard and heavy-duty 7-pin electrical plugs for ease of connection. In addition, ball valve tapes are located in this section, allowing the powerpack hydraulic system to be isolated when the trailers are connected to the traditional log truck fitted with a PTO and cabin-mounted trailer controls.

“We’ve retained the traditional under-bolster electrical and air coupling location, which suits most purpose-built log trucks,” Graeme informed. “However, we’ve added a front-mounted connection point to suit a standard prime mover with Suzi-Coil hoses with both standard and heavy-duty 7-pin electrical plugs for ease of connection. In addition, ball valve tapes are located in this section, allowing the powerpack hydraulic system to be isolated when the trailers are connected to the traditional log truck fitted with a PTO and cabin-mounted trailer controls.

The supplementary air inlet fitting is unique to Elphinstone logging trailers fitted with their EasyAir air transducer ‘On-vehicle’ weighing system, which requires full air pressure in the system to achieve the highest accuracy. This fitting allows a constant supply of air to feed into the trailer air reservoirs regardless of the position of the prime mover’s park or trailer brake switches. The EasyAir air transducer measures air pressure from both sides of the suspension, enabling faster response times. It automatically accounts for atmospheric conditions and variations and then converts this information into a digital weight display in the truck’s cabin.

AutoTensioner

AutoTensioner

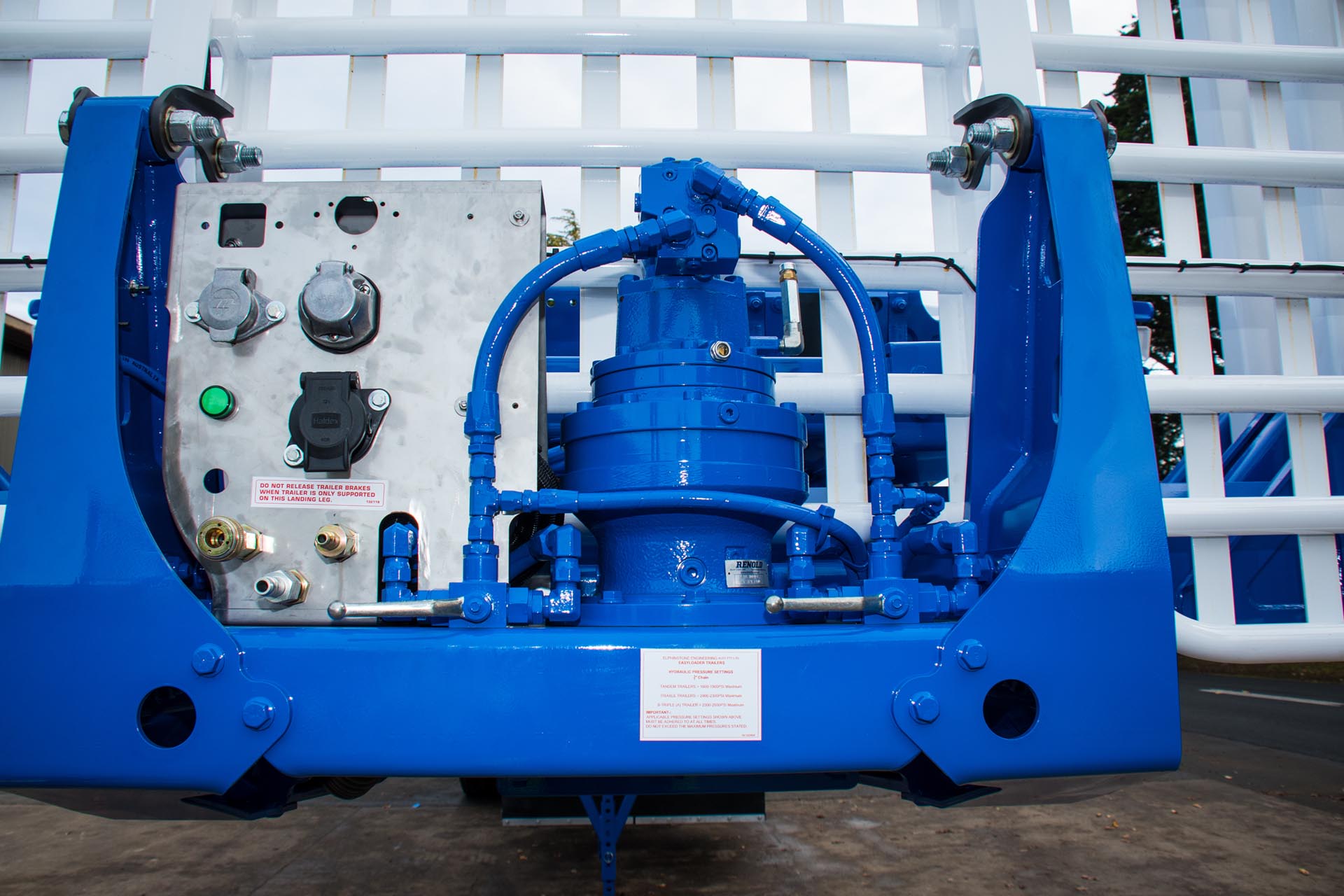

These trailers feature Elphinstone’s ‘AutoTensioner’ air load-binder winch, an air-operated auto tensioner load restraint device that will take up tension on the strap and maintain constant pressure on the strap while travelling.

“We are always listening to our customers, and in the early 1990s, they were raising concerns about the problems they were having with existing load restraint equipment in the field. So we commenced designing and building our own winches to address these problems,” Graeme explained. “Aside from improving the ease of operation and maintenance, we saw a need to include more pre-tension into our design for added safety. Several mounting options are available: frame mount, under tray mount and bolster mount. Our load binders, whether manual or automatic tensioners, are safe, strong and made locally in Australia for Australian Conditions. Importantly, our winch mounting brackets are engineered to match winch capacity.”

During transit, if the load moves or compacts, the winch will automatically activate to maintain the correct tension on the load. It has a lashing capacity of 5000 kg. These winches comply with AS/NZS-4380:2001 Motor Vehicles – Cargo Restraint Systems. Conversely, if, for any reason, there is a problem with air supply or controls, the winch will lock as if it is a manual winch. Furthermore, the winch can revert to manual operation if there are any air supply problems.

“Because clean air is critical for the accurate operation and longevity of the ‘EasyAir’ air transducers and ‘AutoTensioner’ components on the trailer, we conveniently locate all the air drain pull cords on the chassis,” Graeme explained. So the driver can quickly drain any moisture from the tanks regularly. The air drain pull cords are colour-coded blue for easy identification. We also install air filer to supply regulator.”

“For added safety, the winch straps have remote release mechanisms to minimise the need for the driver to walk around the left side of the trailer when unloading,” Graeme added. “We’ve colour coded the remote release pull chords yellow.”

Cab Guard

Cab Guard

Additionally, these trailers come with load restraint guards that comply with Forest Safety Code (Tasmania 2007) S12.2 for Cab Shielding. Each guard is securely mounted in rubber bushes that eliminate vibration from the vehicle and includes a generous radius on all outer edges to minimise operator injury. Conversely, this mounting system prevents distortion and damage to the guard. The guard can restrain a load of 500N applied horizontally at any point on the structure, which disperses over an area of a 400mm diameter circle, and is capable of withstanding inertia forces generated during vehicle braking with logs as small as 50mm diameter. Furthermore, the guards can withstand wind forces generated when the vehicle travels at 100km/h, and they are high enough to restrain all the logs on the load. Moreover, because the cab guard’s location is on the trailer chassis and not the prime mover, it is always in line with the logs on the trailer.

“The efficiency in modern log haulage has unquestionably transformed where timber is sourced and milled,” Graeme said. “We have one customer in Tasmania transporting logs to Victoria for milling. It’s very costly to send a driver and dedicated logging prime mover across on the ferry with the B-Double trailers merely to use the prime mover’s PTO to load the empty trailers for the return journey.”

Optional Remote control for Self-Loading power pack

“The ‘Self-Loader’ powerpack option now saves thousands of dollars in shipping costs because only the trailers make the crossing on the ferry. Now a standard prime mover collects the loaded trailers from the port in Melbourne and delivers the logs to the sawmill. When the trailers are empty, the driver starts the powerpack and loads the rear trailer onto the lead trailer for the return journey to Tasmania.”

While the ‘Self-Loader’ powerpack option enables the EasyLoader trailer to function when connected to a standard prime mover, Graeme advises that a remote hand-held EasyWeigh reader is required for operators to realise the full protentional of the trailer’s advanced on-vehicle weighing system. But for the most accurate weight reading, a pair of fifth wheel loadcells should be fitted, to the prime mover, enabling the most precise weighing of the entire payload.

One benefit for Elphinstone customers is EasyLoader’s modular bolt-on option design allows the ‘Self-Loader’ powerpack option to be easily retrofitted to existing trailer combinations.

“We often refurbish older trailers for customers,” Graeme said. “It’s something we’ve always done, especially when they get a new prime mover. We remove the trailer from the old truck, perform any repairs and updates, and even sandblast and repaint it if the customer requests a new paint job. Then we fit it to the new prime mover and commission it to ensure it functions correctly.”

Graeme Elphinstone demonstrates the onboard vehicle weighing system to new drivers in Eden.

On-vehicle Weighing Systems

“We stand by our statement that Elphinstone On-vehicle Weighing Systems are the most accurate system available in the world today,” Graeme states unequivocally. “If the system is fitted and maintained correctly and the operational procedure adhered to, our onboard weighing system tolerance is +/- 1 per cent of actual payload. We’ve certainly proven time and time again over 50 consecutive loads that our onboard weighing system can be within 0.5 per cent of the payload.

“Our scales are so accurate now that I’ve heard of some operators that will toss a stone on the load just to bring the weight up a few kilograms. That’s how finicky and precise some operators get with their loads.”

The evolution in technology is growing at an exponential rate. Thankfully for Elphinstone Engineering/Weighing Systems, their onboard weighing system will tick all the boxes for the TCA Smart OBM system (Category B), used with the NHVR Intelligent Access Program (IAP) for Higher Mass Limits (HML).

“Our current onboard weighing systems are ‘upward compatible’, which means that we can easily make software upgrades if and when required,” Graeme adds. “Our systems currently communicate and supply raw data to in-vehicle units (IVU) like MT-DATA/Navman. So, for instance, if they make changes to their systems, we can adapt to suit their updates.”

Elphinstone Engineering has indeed kicked a goal for their customers’ bottom line by introducing their ‘Self-Loader’ powerpack option that seamlessly integrates into their Easyloader trailer platform.

For more information contact: info@elph.com.au