Commer was a British truck manufacturer founded in 1905 as Commercial Cars Limited. Their primary business was manufacturing commercial vehicles, including car-derived vans, through to medium and heavy trucks and buses. In addition, they made engines, including their most famous, the TS3 Diesel.

If you’ve got a senior’s card, you’ll undoubtedly remember the distinct sound of an approaching Commer Knocker. Old Timers memory may cause you to forget that your missus asked you to bring home a carton of milk earlier that morning, but the sound of a Commer TS3 is one memory that’s unforgettable even fifty years on.

Now I’ll never admit, especially within earshot of my wife, that I occasionally watch truck videos on YouTube. But if you’ve never heard of a Commer TS3, you’re in luck, as there are a few good videos on YouTube with them in action. To get the whole experience of what it was like to drive one of these machines during the fifties and sixties, turn the sound up loud. They were deafening inside the cabin.

Roll up to any country truck show, and chances are you’ll spot one or two examples in various stages of restoration right through to some in concourse condition. Of course, many enthusiasts have variations on what option was fitted to what model and exactly when the company introduced a new component, etc. Truth be told, it makes for an exciting afternoon’s discussion.

Rootes Motors Limited purchased Commer in 1931 and sold the business to the Chrysler Corporation in 1967.

Even by today’s standard, the TS3 Diesel was an unusual engine. It’s a two-stroke design that consists of three cylinders in a horizontal layout, each with two pistons with their crowns facing each other. Consequently, it was known as an opposed piston engine because of its design.

The base of the piston is attached to a connecting rod and a series of rockers. It then attaches to another connecting rod, which connects to the single centrally located crankshaft at the bottom of the block. However, unlike other opposed piston engine designs, the TS3 only used one crankshaft rather than two. Understandably given the engine’s two-stroke scavenging air intake system, it is supercharged, with an enormous rotating lobe blower force-feeding air to the intake manifold.

It was a rather compact engine with only 3.25-litre displacement, yet relatively powerful given its size, delivering 105 HP (78.29kW) with a massive 270 lb-ft (366Nm) of torque. However, compared to other diesel truck engines of the time, the TS3 was extremely powerful and achieved an output comparable to engines of a much larger capacity. Moreover, the TS3 power-to-weight ratio is exceptional because the design dispenses with various components such as a cylinder head, camshaft and valve gear. As a result, it delivers high thermal efficiency, which is the foundation for minimal fuel consumption.

It was a rather compact engine with only 3.25-litre displacement, yet relatively powerful given its size, delivering 105 HP (78.29kW) with a massive 270 lb-ft (366Nm) of torque. However, compared to other diesel truck engines of the time, the TS3 was extremely powerful and achieved an output comparable to engines of a much larger capacity. Moreover, the TS3 power-to-weight ratio is exceptional because the design dispenses with various components such as a cylinder head, camshaft and valve gear. As a result, it delivers high thermal efficiency, which is the foundation for minimal fuel consumption.

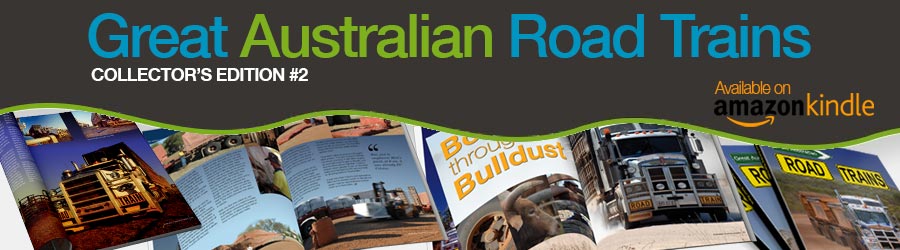

The engine utilised a modified two-stroke compression cycle where one piston is known as the exhaust piston, and the other is described as the air piston, as indicated by the corresponding port above each piston.

The exhaust piston has a smaller lead than the air piston; this ensures the exhaust port gets sealed as fresh air rushes into the cylinder. As the pistons converged on each other, the air piston closed the inlet port, and the compression cycle commenced, Image-1. Then just before the two pistons meet, fuel is injected into the cylinder, Image-2, igniting soon after by the intense heat and pressure.

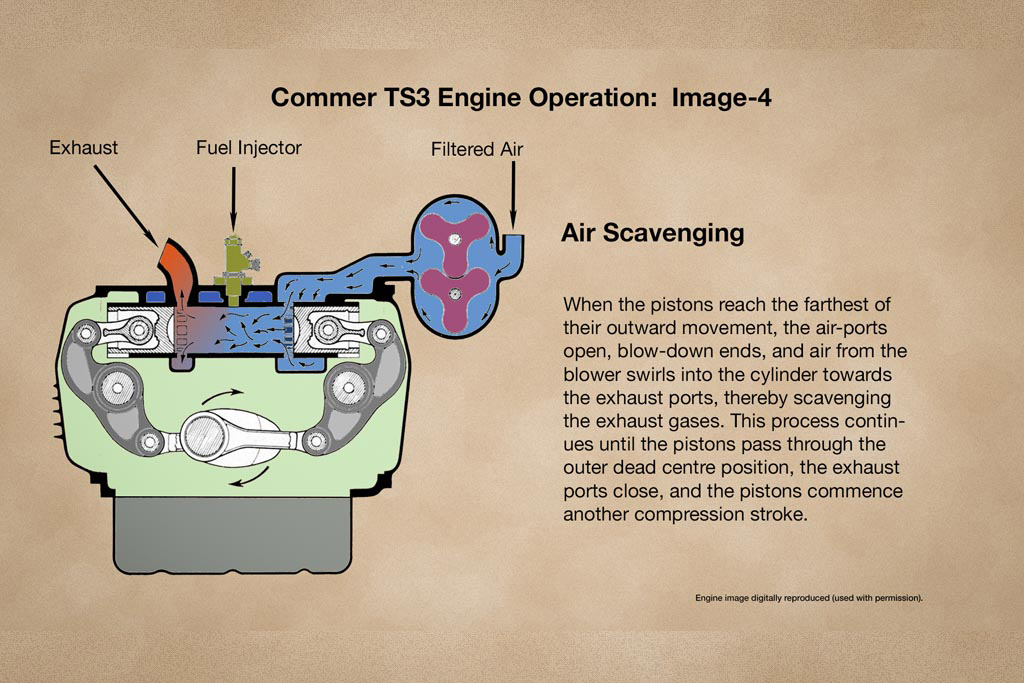

The resulting explosion in the cylinder forces the pistons apart, Image-3, and the power cycle commences. As the piston passes the exhaust port, gases get expelled through the exhaust port. Once both pistons reach the outer dead centre position, Image-4, the air intake port is exposed, and the cycle begins again.

The compact design of the TS3 enabled Rootes to slot the engine under the ‘QX’ cab forward cabin fitted to the R7 (7-ton) truck released in 1948. One selling point highlighted in advertising material at the time was that the advanced compact engine design “allowed room for three men to fit comfortably across the cab”.

The compact design of the TS3 enabled Rootes to slot the engine under the ‘QX’ cab forward cabin fitted to the R7 (7-ton) truck released in 1948. One selling point highlighted in advertising material at the time was that the advanced compact engine design “allowed room for three men to fit comfortably across the cab”.

Surprisingly, access for maintenance was better than you’d think. A small hatch inside the cab provided access to the oil and fuel filters, the injection pump and injectors. Meantime removable doors on either side of the cab allowed access to remove the connecting rods and pistons without removing the engine from the truck. The simplicity of the engine design meant there were no camshaft or valves commonly found in conventional engines that required removal. Even the blower could be removed easily from the front of the cabin after removing the radiator. Removing the engine from the truck for repair was only necessary if the crankshaft bearings required attention.

As stated earlier, the Commer Knockers had a distinct exhaust bark you’d hear for miles. Despite this, it wasn’t the distinctive exhaust bark that earned the Commer’s their Knocker reputation, as some folks believe. However, here in Australia and New Zealand, they were prevalent. And where they earned their Knocker reputation. Because export versions of the TS3 engines were shipped with the larger Clayton Dewandre SC-9 compressor with no damper. Meanwhile, local UK models had the Clayton Dewandre SC-6 compressor, which came standard with a harmonic balancer. Consequently, as export TS3 engines got a few miles under their belts and the timing gears became worn, the engines began to produce their now infamous knock, knock sound at idle.

As stated earlier, the Commer Knockers had a distinct exhaust bark you’d hear for miles. Despite this, it wasn’t the distinctive exhaust bark that earned the Commer’s their Knocker reputation, as some folks believe. However, here in Australia and New Zealand, they were prevalent. And where they earned their Knocker reputation. Because export versions of the TS3 engines were shipped with the larger Clayton Dewandre SC-9 compressor with no damper. Meanwhile, local UK models had the Clayton Dewandre SC-6 compressor, which came standard with a harmonic balancer. Consequently, as export TS3 engines got a few miles under their belts and the timing gears became worn, the engines began to produce their now infamous knock, knock sound at idle.

Understandably, shrewd operators monitored their fuel economy even back in the fifties. The Commer TS3 engines were extremely economical, even by today’s standard. A Commercial Motor road-test from 1955 reported that a ladened TS3 Commer travelled 49,000 miles (78,857km) and returned an average of 20.25mpg (0.425km/L). The report states that the vehicle leaves the depot with 8-ton and makes 20 drops per day.

James Powell, who supplied most of the images, agrees and says his restored 1955 TS3 Commer is exceptionally economical to run. Moreover, he has an ex 1943 50-foot RAAF 02-15 WW2 Pilot Recovery boat powered by twin TS3 engines and reports a fuel economy of 11 litres per hour.

James Powell, who supplied most of the images, agrees and says his restored 1955 TS3 Commer is exceptionally economical to run. Moreover, he has an ex 1943 50-foot RAAF 02-15 WW2 Pilot Recovery boat powered by twin TS3 engines and reports a fuel economy of 11 litres per hour.

During 1964, Commer raised the power output of the TS3 to 117 HP (87.24kW) and 310 lb-ft (420 Nm) torque to coincide with the introduction of a 16-ton Commer Maxiload model.

Yet it wasn’t until I read a report conducted by Transport Engineer magazine in the UK that it truly hit home how advanced the Commer TS3 Diesel engine was for its time and why it endured almost two decades of production. In the Transport Engineer issue dated August 2001, they conducted a noise and emissions test between a MAN 18.224, Isuzu NQR, Mercedes-Benz Sprinter 413CDI, and to make it interesting, a 37-year-old TS3 Commer. The average drive-by noise at 50kph results was unexpected; MAN 84dbA, Isuzu 79dbA and Commer 78.4dbA. The MAN regained some face in the emissions testing proving to be the most environmentally friendly with only 7 particulates (mg/cu m). The Mercedes-Benz Sprinter result was 11 particulates, and the Commer TS3 was 55 particulates. Nevertheless, when it came to fuel economy, the 37-year-old TS3 Commer made the podium amid a field of young upcoming stars and wannabes.

The Commer TS3 Diesel enjoyed an astonishing 18-year production run from 1954 to 1972.

Commer TS3 Engine Specs

Commer TS3 Engine Specs

Model: TS3

Type: 3-Cylinder, Opposed Piston Uniflow port

Power: 105HP (78kW) at 2,400RPM

Torque: 270 lb-ft (366Nm) at 1,200RPM

Fuel: Diesel

Bore: 3.25-inch (83mm)

Stroke: 4-inches (102mm)

Displacement: 200 cu-in (3.26L)