The Abby Transporter is revolutionising the transport of large bulk construction items bringing greater efficiencies and safety to the building industry.

Most days, mid-morning traffic flows well along Woolcock Street, Townsville. However, This morning, there were laboriously long road works, and traffic had slowed to a crawl.

In the rearview mirror, a brilliant red Freightliner Argosy Evolution loomed closer and commanded a second glance. It was a second glance well worth having because not only was the ten-year-old Freightliner Argosy Evolution impressive, but the trailer it towed was a work of art in itself. A few minutes later, after a quick phone call to the number on the door of the Argosy, I secured a meeting for later that afternoon with Abby, Group CEO, Danys Bentancur.

To survive in the trucking business, you need to be efficient, productive and, above all, innovative. This philosophy is at the core of Abby Transport and has driven them to do what many in the construction industry thought was impossible: develop and revolutionise a transport system. “What you are looking at is a result of years of continuous development and refinements,” Danys told us.

“We were traditionally in the business of building pre-cast concrete panels around the Sydney area,” he explained. “However, we were having a lot of trouble at the time meeting our customers’ deadlines through the inefficiencies in the current constraints of road transport and crane availability.

“We were traditionally in the business of building pre-cast concrete panels around the Sydney area,” he explained. “However, we were having a lot of trouble at the time meeting our customers’ deadlines through the inefficiencies in the current constraints of road transport and crane availability.

“On top of that, our annual transport bill kept going up. I think we had paid one transport company in excess of $70,000 over one quarter to transport our pre-cast panels around Sydney.”

According to Danys, there simply had to be a better way to deliver his pre-cast concrete panels. Driven by a need to reduce costs, he somewhat reluctantly entered the transport industry. It took a lot of thought, and he admits he drew on ideas and concepts he’d seen in Europe before coming up with his unique “Abby Transporter, “essentially a trailer that can unload and load itself.

“The Abby Transporter has been designed to provide a rapid and cost-effective solution to moving materials across all industries and product types – with an emphasis on oversize loads,” Danys revealed. “It is Australia’s first self-loading trailer that has dramatically improved efficiency and created a new benchmark in transport safety.

“The Abby Transporter features a list of advantages that are simply unmatched by other transport modes,” Danys explained. “From its pre-packing ability that dramatically reduces load and downtime to its continuous ‘flow’ – no more waiting for improved loading or unloading conditions – no other transport system comes close,” Danys added. “The Abby Transporter has a payload capability of 24 tonnes, a maximum height of 4.6 meters and a pallet length and width of 9.4 meters and 1.4 meters, respectively.

“The Abby Transporter features a list of advantages that are simply unmatched by other transport modes,” Danys explained. “From its pre-packing ability that dramatically reduces load and downtime to its continuous ‘flow’ – no more waiting for improved loading or unloading conditions – no other transport system comes close,” Danys added. “The Abby Transporter has a payload capability of 24 tonnes, a maximum height of 4.6 meters and a pallet length and width of 9.4 meters and 1.4 meters, respectively.

Other key technical advantages of the Abby Transporter include smoother road handling than traditional rigid-axle trailers, a lower centre of gravity for additional stability with high loads, adjustable travel height for difficult terrain and an axle design featuring high-lifting capacity. It also offers fast loading of pallets (frame) by quick lifting ability with minimal stress on transport material within the chassis frame.

Basically, how the system works is simple enough. Once the pre-cast panels have cured enough to be handled, they are removed from their framework via an overhead crane in the panel shop and then stood in the purpose-built frames, ready for transport to the job site. The panels are delivered in the order in which they need to be erected, which also adds efficiencies at the construction site.

Basically, how the system works is simple enough. Once the pre-cast panels have cured enough to be handled, they are removed from their framework via an overhead crane in the panel shop and then stood in the purpose-built frames, ready for transport to the job site. The panels are delivered in the order in which they need to be erected, which also adds efficiencies at the construction site.

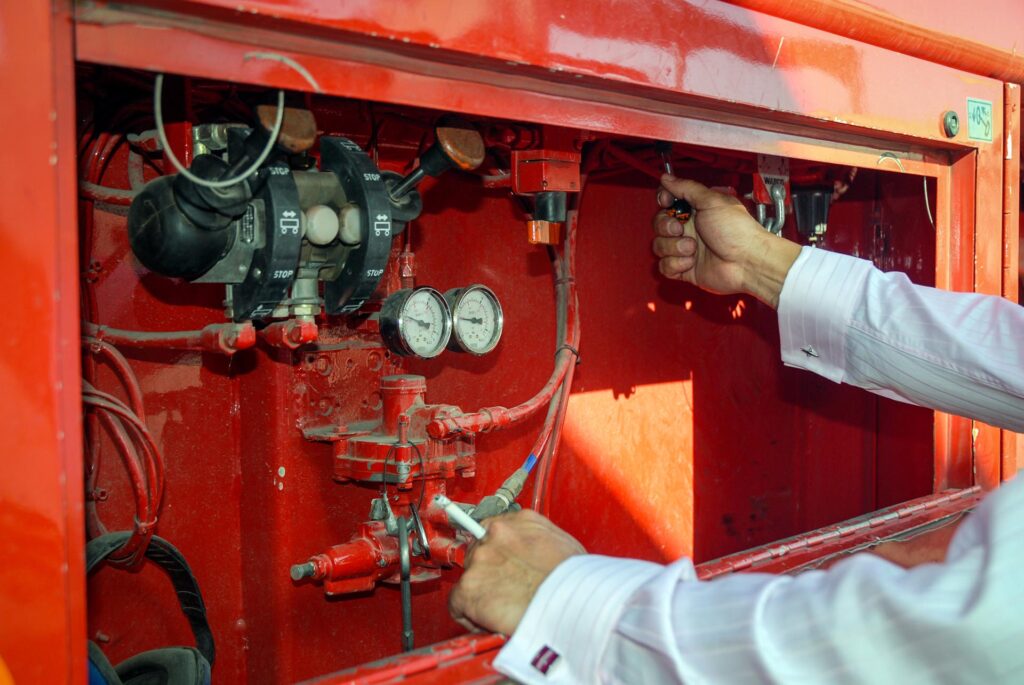

A series of control levers on the right side of the trailer allows the operator to lower the trailer to accept the purpose-built frame. Once the frame is inside the trailer, it is raised up to the travelling height, and the rear safety door is closed. At the job site, the frames are strategically placed to enable the efficient erection of panels. Another advantage is that one truck can deliver all the frames prior to the arrival of the crane, which means a significant saving on crane hire compared to the conventional method of delivering the panels.

Also, because the Abby Transporter can carry higher and longer panels than a traditional drop-deck or semi-trailer, architects can take advantage too in the design phase, meaning that fewer panels are required to erect a building, revealing vast savings on the construction side of the operation. Danys showed us a cost-savings model, which revealed a reduction of 10 conventional panels, which equated to 40 less crane lifts.

Why Freightliner?

Why Freightliner?

Hauling the unique Abby Transporter trailer is, of course, the Freightliner Argosy Evolution. This is one of six Freightliner Argosys in Danys fleet.

“In Sydney and Melbourne, we have traditionally run with the Mercedes Benz Actros,” Danys explained. “However, up here in the north, we have much farther distances to cover. For example, we’re now quoting on jobs as far as Port Douglas to the north and Mount Isa to the west. So we are considering constructing a B-Double version of our Abby Transporter to add more efficiency to our transportation.”

“We just felt that the bigger Freightliner was more suited to the longer distance haulage. Don’t get me wrong, we really love our Actros, and they do a terrific job where they are. But it is all about getting the right truck for the right job, and with the wide variety of trucks and brands under the Daimler umbrella, we can get them all serviced at the one dealer, which really helps from an operational perspective.”

Danys specifies his Freightliner trucks with Detroit engines, the latest Eaton ultra-shift transmissions, and Mercedes Benz Actros with full MB running gear. He utilises Daimler’s full-service agreements for added up-time and to ensure the fleet is constantly in first-class mechanical condition. He adds that the five-year/800,000-kilometre warranty gave him some additional peace of mind.

Danys specifies his Freightliner trucks with Detroit engines, the latest Eaton ultra-shift transmissions, and Mercedes Benz Actros with full MB running gear. He utilises Daimler’s full-service agreements for added up-time and to ensure the fleet is constantly in first-class mechanical condition. He adds that the five-year/800,000-kilometre warranty gave him some additional peace of mind.

“We believe that our Abby Transporter has moved Australian transport to a new level,” Danys said. “That’s because it is designed for use across all industries and product groups. In particular, the Abby Transporter’s unique design provides the extra height and weight loading capacity for more challenging loads and the advantages of rapid load and unload – a remarkable three minutes. From a safety perspective, clients also benefit from a hands-free load and unload system.

“But most of all, we’re saving money where it counts – the bottom line,” Danys said.